Non-financial Information(ESG)

Approaches to Environment

Environmental Management

Makita has established and run its own environmental management system since 1998. For the purpose of leveraging that system as a tool for mitigating environmental burdens, our Head Office and Okazaki Plant first received ISO 14001 certification in 2007. In later years, our Nisshin Office and all of our overseas production bases received the certification and are now operating environmental management systems.

We promote the protection of the environment at all of our business bases mentioned above and carry out activities, such as Internal Environmental Audits and environmental education, based on the requirements of the certification.

Responding to Climate Change

Initiatives in our Business Activities

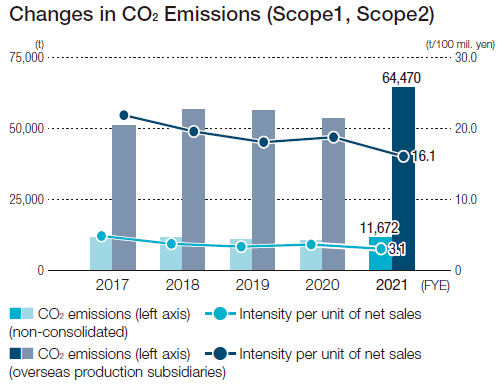

Our efforts toward reducing CO2 emissions include pursuing efficiency gains for energy-consuming equipment in our offices by, for example, installing LED lighting and high-efficiency equipment (AC units, compressors, manufacturing machinery, etc.). In FYE 2021, our Head Office and Okazaki Plant collectively saved 47,719 kwh of electricity by switching to LED tubes. Additionally, photovoltaic panels will be installed gradually at our sales bases we own in Japan. We are also promoting the use of renewable energy overseas, where some subsidiaries have adopted a heating and cooling system using geothermal heat. In order to raise employees’ awareness of the environment, we also carry out awareness activities.

These include distributing energy-saving promotional material to employees and making regular inspections checking energy-saving responses in offices and plants.

Initiatives with Our Products

Outdoor power equipment has conventionally been engine powered, which had a major impact in environmental terms due to exhaust gas. In October 2020, the Japanese government made a proclamation to “achieve net-zero CO2 emissions by 2050,” which is basically a commitment to achieve a decarbonized society. This, coupled with the U.S.’ decision to rejoin the Paris Agreement, comes amidst raising awareness on environmental issues. Within this context, Makita is contributing to achieving a decarbonized society by putting effort into our cordless outdoor power equipment with zero exhaust gas emissions during use. Also, in light of these circumstances, Makita has decided to stop manufacturing engine-powered products on March 31, 2022.

Going forward, Makita will further focus operating resources on developing, anufacturing, and selling cordless products that effectively feel as if they are engine-powered. In this way, we will accelerate the shift from exhaust-emitting engines to clean-running cordless electric motors and will contribute to achieving a zero-emission society in the future.

Promoting the Elimination of Plastic

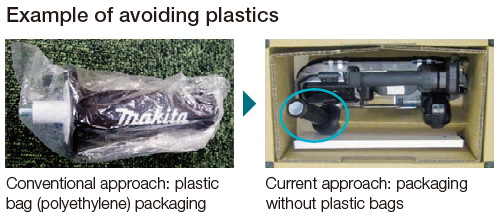

Due to concern over global environmental pollution from plastic waste entering oceans, the EU passed a law in June 2019 prohibiting the use of certain singleuse plastic products.

In Japan as well, social initiatives are making progress to reduce single-use plastic, including the July 2020 regulation to charge for plastic shopping bags. In order to achieve a sustainable society and contribute to preserving biodiversity, Makita is also striving to reduce single-use plastic used in our product packaging. In addition to efforts to simplify our standard packaging, we have, since FYE 2021, tried to reduce plastic bags and the like used in product packaging, and have been proceeding to replace them with paper and other environmentally friendly materials. In March, 2021 (the last month of the first fiscal year of this new initiative), we achieved the equivalent of a nearly 40-ton yearly reduction in plastic usage. Going forward, we will continue efforts to eliminate the use of plastic.

Zero Emission of Waste Products

In light of the pressing social issues of depleted energy resources and availability of waste disposal sites in the future, Makita has been making progress in reducing our final disposal volume of waste products. On a nonconsolidated basis (applicable to the Head Office, Okazaki Plant, and Nisshin Office), we have been able to hold our final disposal volume of waste products to 1% or lower since FYE 2007. From FYE 2015, we have continuously achieved what we define as “zero emission of waste products” (a final disposal volume of 0.5% or lower).

Battery Recycling

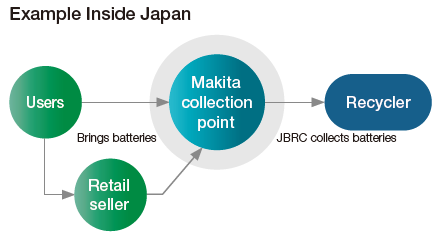

As “a Supplier of a Comprehensive Range of Cordless Products”, and as a company that supplies a large volume of batteries, we believe that, for the sake of environmental protection and the effective utilization of resources, collecting used batteries is a crucial task. Inside Japan, we are a member of the Japan Portable Rechargeable Battery Recycling Center (JBRC). Based on the Act on the Promotion of Effective Utilization of Resources, we are striving to voluntarily collect used batteries and reuse them as resources. In line with government laws and regulatory frameworks in countries outside Japan, Makita is cooperating with retail stores and dedicated organizations to collect used batteries. By building and implementing collection systems in a host of countries and regions, we are working to promote resource recycling.

Reduced Use of Chemical Substances

With regard to the EU’s REACH (Registration, Evaluation, Authorization and Restriction of Chemical Substances) regulations, since FYE 2010 we have promoted investigating, managing, and supplying information regarding carcinogenic and other substances of very high concern (SVHC) contained in our products. SVHC are added regularly, so Makita continuously surveys business partners about the content of their products.

As we pursue the reduction and control of chemical substances, we also continually engage in component procurement in compliance with the RoHS Directive (directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment) adopted by EU member states.

Environmentally Conscious

Makita’s concepts for environmentally conscious products began with a product assessment in 1992 and was followed by the codification of Makita’s Global Environment Charter in 1993, the year that we kicked off our full-fledged development of products that take the environment into consideration.

At the design stage, we have endeavored to improve the energy efficiency, weight, and longevity of new products, while also using materials that are considerate to the environment, as we continue developing tools that can be recycled.