About a year after getting a job, an opportunity arose for Mosaburo. He heard that Meiji Electric, headquartered in Tokyo, had run into financial difficulty and decided to close its branch factory in Nagoya and sell machinery and equipment. Meiji Electric was engaged in manufacturing, selling, and repairing motors and electric transformers in the order of 50 horsepower. Mosaburo enthusiastically asked his father right away for financial assistance and concluded a contract to acquire the machinery and equipment. At the same time, he requested Meiji Electric to dispatch workers as well, and Jujiro Goto was appointed to the task. Nobody would have guessed that Jujiro would later lay down the foundations of the Company.

On-site inspection by inspector from the Soviet Union. The Soviet Union required rigorous inspections for export, but the Company’s products passed them with excellent assessment results. It became Makita’s memorable first export case.

On-site inspection by inspector from the Soviet Union. The Soviet Union required rigorous inspections for export, but the Company’s products passed them with excellent assessment results. It became Makita’s memorable first export case.

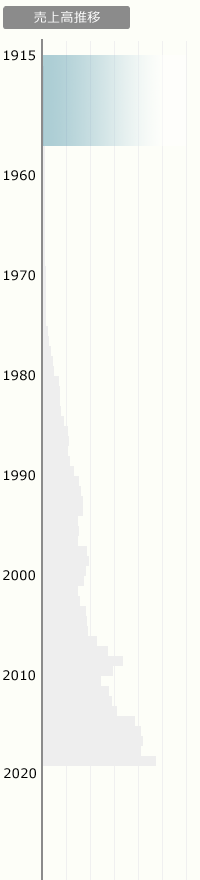

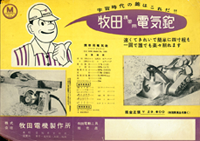

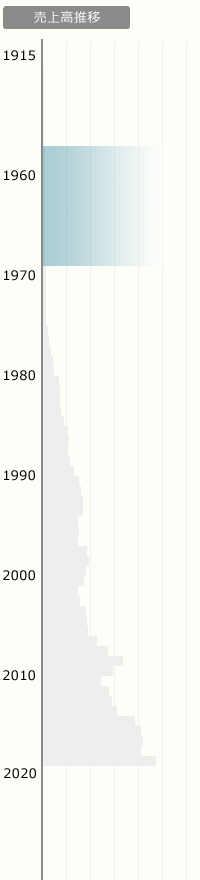

With a supportive push from Jujiro, employees explored seeds of new products. In 1957, the Company embarked on the development of the first domestically produced portable electric planer, for which it could apply its motor production technologies cultivated over the years. In the following year, 1958, the Company, by trial and error, successfully launched the first domestically produced portable electric planer (model 1000). The new product had a production process and customers that were totally different from those of motors, the Company’s previous core product. But employees had confidence in the performance of the product. Model 1000 allowed inexperienced workers to do work as well as experienced workers with a uniform and beautiful finish. In addition, it was a lot less expensive than imports. Shortly after the launch of model 1000, its reputation spread and it gained popularity among builders and carpenters throughout the country. The Company thus transformed into a specialized electric power tool manufacturer.

Catalogue of electric planers at that time

Catalogue of electric planers at that time Changed the notation of the Company’s name from Makita using kanji (Chinese characters) to Makita using katakana (a Japanese syllabary) to make it more approachable in preparation for expanding into the global market.

Changed the notation of the Company’s name from Makita using kanji (Chinese characters) to Makita using katakana (a Japanese syllabary) to make it more approachable in preparation for expanding into the global market.

On the sales and marketing front, Makita established overseas subsidiaries one after another and worked to expand exports. In 1970, Makita established Makita U.S.A., the first overseas subsidiary, and Masahiko Goto (current Chairman and Representative Director) was stationed at the new subsidiary. However, the U.S. is the home to electric power tools, and the U.S. market has numerous makers in fierce competition with each other. Therefore, the Company was unable to turn the situation around for the better. In addition, the yen appreciated rapidly in 1973 following the introduction of the floating exchange rate regime, and Makita U.S.A.’s financial conditions deteriorated. In accordance with the management policy that calls for a “proactive management approach in times of recession,” Makita established sales and service bases in major cities in the U.S., including Chicago and Los Angeles, and provided finely-tuned support to customers’ needs. Amid such situation, the quality of products produced by Japanese manufacturers, such as Toyota and Sony, drew the attention of American consumers, which paved the way for Makita to gradually grow sales in the U.S. market. Subsequently, Makita’s products steadily penetrated the North American market based on the products’ good reputation for cost-effectiveness and the high-quality after-sales services from users and distributors. Makita subsequently established overseas subsidiaries one after another in France, the U.K., and Australia and expanded its market, and its finely-tuned sales and marketing strategies suited to the situation of each country steadily produced results. Makita thus grew into a global company.

Manufacturing and assembly line in Makita Corporation of America.

Manufacturing and assembly line in Makita Corporation of America.

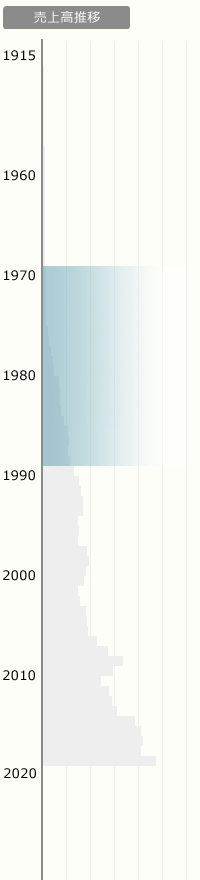

A company cannot avoid foreign exchange risk no matter how much effort a company puts in as long as it continues exporting products. In order to overcome this foreign exchange risk, it is essential that the company enhances local production further. Makita, which had already started local production in the U.S. and Brazil, launched production of power tools in the U.K. in 1991 and in China in 1995. The Company thus promoted a shift in production to overseas factories and transformed itself from an exporting company to a true global company.

On the development front, Makita became the first in the industry to start sales of battery-powered impact drivers equipped with lithium-ion batteries in 2005, successfully increasing the service life of batteries, as well as downsizing products, reducing their weight, and increasing the power of equipment. Also in 2005, Makita launched electric rotary hammer drills equipped with Anti Vibration Technology (AVT), and they achieved a 20% improvement in work efficiency and approx. 30% reduction in vibration compared with conventional models. These lithium-ion battery powered products and AVT-based products had a great impact on the market and led to a dramatic increase in sales for Makita. At the same time, Makita’s high technological capabilities became known all around the world and contributed significantly to boosting the image of the Makita brand. Makita adopted a new company logo mark designed by industrial designer Giorgetto Giugiaro, to make it more accessible to global customers.

Makita adopted a new company logo mark designed by industrial designer Giorgetto Giugiaro, to make it more accessible to global customers.

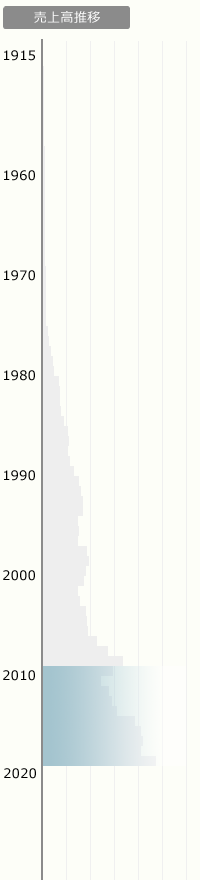

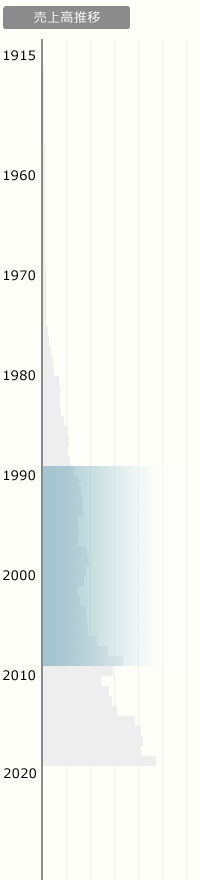

Makita celebrated its 100th anniversary in 2015. One of the major strategies Makita has set with an eye to the next 100 years is “shifting from engine-powered to battery-powered.” By leveraging its proprietary motor and recharging technologies cultivated through power tools, Makita will promote the shift in the mainstream of OPE products from engine-powered to battery-powered. In addition, To create a carbon neutral society, the Company will continue to attempt new things to survive under any business environment.

Started marketing the Gold Color series as the 100th anniversary special model.

Started marketing the Gold Color series as the 100th anniversary special model. Launched a series of cordless tools with higher power, longer lifespans, and higher durability than conventional cordless versions. Continued to further technological innovation by outfitting systems to optimize charging/discharging.

Launched a series of cordless tools with higher power, longer lifespans, and higher durability than conventional cordless versions. Continued to further technological innovation by outfitting systems to optimize charging/discharging. Accelerated the replacement of engine-powered products with cordless products. Terminated the production of engine-powered equipment to help promote decarbonization.

Accelerated the replacement of engine-powered products with cordless products. Terminated the production of engine-powered equipment to help promote decarbonization.